The other hand The Clients are also Beneficiary through form of Turnkey Basis, because we calculate the actual required Quantity of

each Electrical Item, so it does not gone waste or laid unnecessary dead stock on clients head, and we are also committed to received all

remain Electrical items get back in terms of Contract Manual.

We are performing various type of Industrial and Commercial Electrical Installation work on ( Turnkey Basis - Supply and Installation )

Installation of 66KV / 11KV Switchyard and Equipments. ( Primary Distribution )

Installation of 11KV DP Structure, Power & Distribution Transformers, HT VCB, RMU & LBS Panel, HT Cable, HT Cable Joint kit,

Excavation of Cable Trench.

Installation of LV Distribution ( Secondary Distribution )

Installation of Main LT Panel, APFC Panel, PDB, LDB and MCC Panel.

Laying of LT Cables, Cable Termination end Joint, Cable Tray Installation work, MS Fabrication work, Industrial Point wiring,

Industrial Lighting Distribution, MCB & MCB Distribution Boards, Highbay & Lowbay Lighting Installation, Street Lighting Pole,

Industrial Earthing & Earthing Strip.

Installation of Commercial & Residential Electrical Projects.

Installation of FSP ( Feeder Section Pillar ), MSP ( Main Section Pillar ), & SSP ( Sub Section Pillar ), Residential Infra Under

ground Projects, Under ground cabling work, Cable Joint end termination, Open and Concealed house wiring, Lighting DB, Installation of

House Appliances, Street Light Pole, Gate top post lamp.

Panel Manufacturing

We are Manufacturing Various Type of Customized Power and Control Panels.

PCC Panel ( Power Control Center Panel )

|

APFC Panel ( Automatic Power Factor Control Panel )

|

MCC Panel ( Motor Control Centre Panel )

|

Bus ducts & Busbar Trunking System )

|

PDB Panel ( Power Distribution Board )

|

LDB Panel ( Lighting Distribution Board )

|

Industrial Automation & PLC Panels

|

VFD Panel ( Variable Frequency Drive Control Panel )

|

MSP ( Main Section Pillar )

|

FSP ( Feeder Section Pillar )

|

We are team of Expert & Experienced Electrical Engineers in the field of Power Distribution & Electrical System Design, Our design capability

is very uniform to meet all the criteria of Electrical Safety Codes & Customer satisfaction.

Sheet metal and Painting

We always fabricate the panels with CRC Sheets and it purchase from steel authority of India and, sheets are checking in strict supervision

of WPP employee to ensure that thickness of the Sheets & Physical damage during transportation.

The fabricators are guide by Client's Approved Modified Drawings to fabricate the Panels. when the Panel is fabricated as per the approved

drawing, it will be transfer to the Powder Coating Plant.

In the Powder coating Plant it is send to either Seven tank process or Sand blasting Process to make the sheet metal free from Rusting,

Oil & Greasing. After Cleaning surface of the metal , Epoxy based powder paint is spray on the Panel. Panel is kept for drying in the Oven.

In the oven temperature is set to the required temperature of melting point of epoxy powder paint. Once the drying is done.

As the paint is complete the quality team insure the paint quality, After quality assurance, the Panel is ready to Assemble.

Electrical Parts

Electrical parts are the main components of Panel manufacturing process. Various range and verity of parts are available in the market,

so normally is selected by the Client according to the type of industry, Weather Condition, Rated Voltage & Current, type of power supply,

Financial Capability, Availability of Spares after Installation.

WPP team inspects all the purchased Electrical Parts by Visual Inspection to find physical & manufacturing damages during Transits.

After Verification selected Electrical parts are ready to assemble.

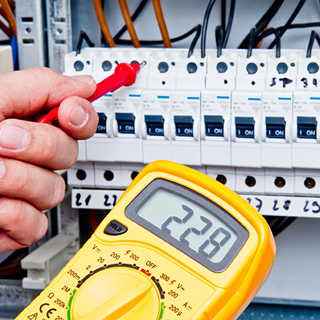

Assembly Process & Testing

In this process Electrical Parts are assemble to the Powder coated Panel, The panel is assemble as per costumer’s Bill of Material as well as

Approved General Arrangement & Schematic drawings and Specification.

Ones the panel is ready at shop floor after assemble process the next turn is for Panel Quality Process. Mainly four type of tests are

carried out for testing of Panels at our Shop Floor. Testing process is done in the specified area of the shop floor by the team of

expert & experienced Engineers. The tests are carried out in present of Client or Inspector.

|

Visual Inspection Test

|

Functional Test

|

|

High Voltage Test

|

Insulation Resistant Test

|

After the satisfactory test results, the panel is ready to Packing, ( We are doing packing as per client’s requirement either

Paper/Plascic or Wooden ).

And finally the Panel is ready to Dispatch.

Electrical Liaisoning & Consulting

We have very qualified Legal team to perform Liaisoning work in all criteria & Divisions,

UGVCL , PGVCL, DGVCL & MGVCL Liaisoning Work

HT & LT Power Supply

|

New Power Supply

|

Additional Power Supply

|

Change of Name

|

Reduction of Power Load

|

Shifting of Point of Power Supply

|

Merge & Extension of Area

|

Load Reduction – HT to LT

|

66KV Switchyard & 66KV Line

|

Demerge of Area & Power

|

Additional Load – LT to HT

|

Infra Under ground Approval.

|

GUVNL and GERC Related Special Approval & Cases

|

Electrical Inspector & Elect.Duty Liaisoning Work

Approval & Inspection of Transformer Installation

|

Approval & Inspection of DG Set Installation

|

Electricity Duty Exemption Benefit

|

Approval of 66KV / 11KV Switchyard & Equipments

|

Annual Inspection of Electrical Inspector

|

High rise Building Approval

|

Approval of Captive Power Plant

|

Industrial Energy Audit

|

Energy Management System

WPP has wide experience of Energy Saving & Power Management system, through our knowledge excellence and fundamental consumption of energy.

Power management system shows the flow & Quantity of the power where it is flowing, where we are wasting our unwanted energy, by the system

we can save maximum amount of Energy.

Electrical Consulting Work

We are providing Consulting service for Industrial & Commercial Projects in the field of Electrical.

Plant Layout, Schematic Drawings, SLDs ( Single Line Diagram ), Switchyard Approval Drawings, DG Set Approval Drawings, Cable & Cable

tray arrangement, Structural Drawings, Guidance of Civil Foundation & Cable Trench, Lighting Distribution, LT Panel Installation Drawing.

Power Distribution & Power Management, Third Party Inspection for Testing of Electrical Equipments.

Electrical Shutdown & Breakdown Job

We are also providing Service for Shutdown & Breakdown Job, We are expert to manage our work Schedule in time limit as Industrial Norms requires.

Jobs Includes.. Transformer Replacement, Cable Laying, Busduct Installation, LT Panel, HT VCBs/RMU Replacement, 11KV DP Structure Servicing job,

Maintenance and servicing of 66KV Switchyard and Equipments.